PILLARS OF SUSTAINABILITY AT MELISSA

Our journey is built on two pillars: circularity, which values resources through new beginnings, and responsibility, which is how we care for processes and people.

CIRCULARITY

The pursuit of a circular model inspires us at every stage, from pre- to post-consumption. It begins with the choice of Melissa’s raw material, Melflex. Next comes the shoe design project, which already considers the lowest possible impact. After an eco-efficient production process, the shoe goes out into the world. And, at the right time, the loop closes. This cycle is made possible by our Reverse Logistics Program, a pioneer in Brazil.

RESPONSIBILITY

We’re always looking for ways to improve our production methods. From our factories to our stores, we want Melissa to be the best company possible for people and the planet. That’s why we are working together to implement the profound changes this moment calls for.

SUSTAINABILITY INSPIRES EVERYTHING WE DO AT MELISSA. DISCOVER OUR MAIN STRENGTHS:

RAW MATERIAL

At Melissa, we’re constantly evolving our research into new materials and technologies, making our products ever better and setting them apart in the global market.Melflex is Melissa's starting point: today’s best choice for creating fashion with lower social and environmental impact, and increasingly circular. Why? It’s a durable, recyclable raw material produced with a low carbon footprint.

Throughout our history, we’ve led innovation in plastic footwear.

Now that same commitment is driving us toward greater sustainability.

Here are some of our advances:

We prioritize the use of recyclable materials, like Melflex, and incorporate recycled raw materials into the composition of our products.

Our Reverse Logistics Program allows for the proper disposal of products after use, closing the loop.

When designing our shoes, we opt for assemblies and fittings that facilitate recycling.

We reduce the environmental impact of packaging by using FSC-certified paper and ensuring it can be reused and/or recycled.

We conduct research and develop new raw materials with a lower environmental impact.

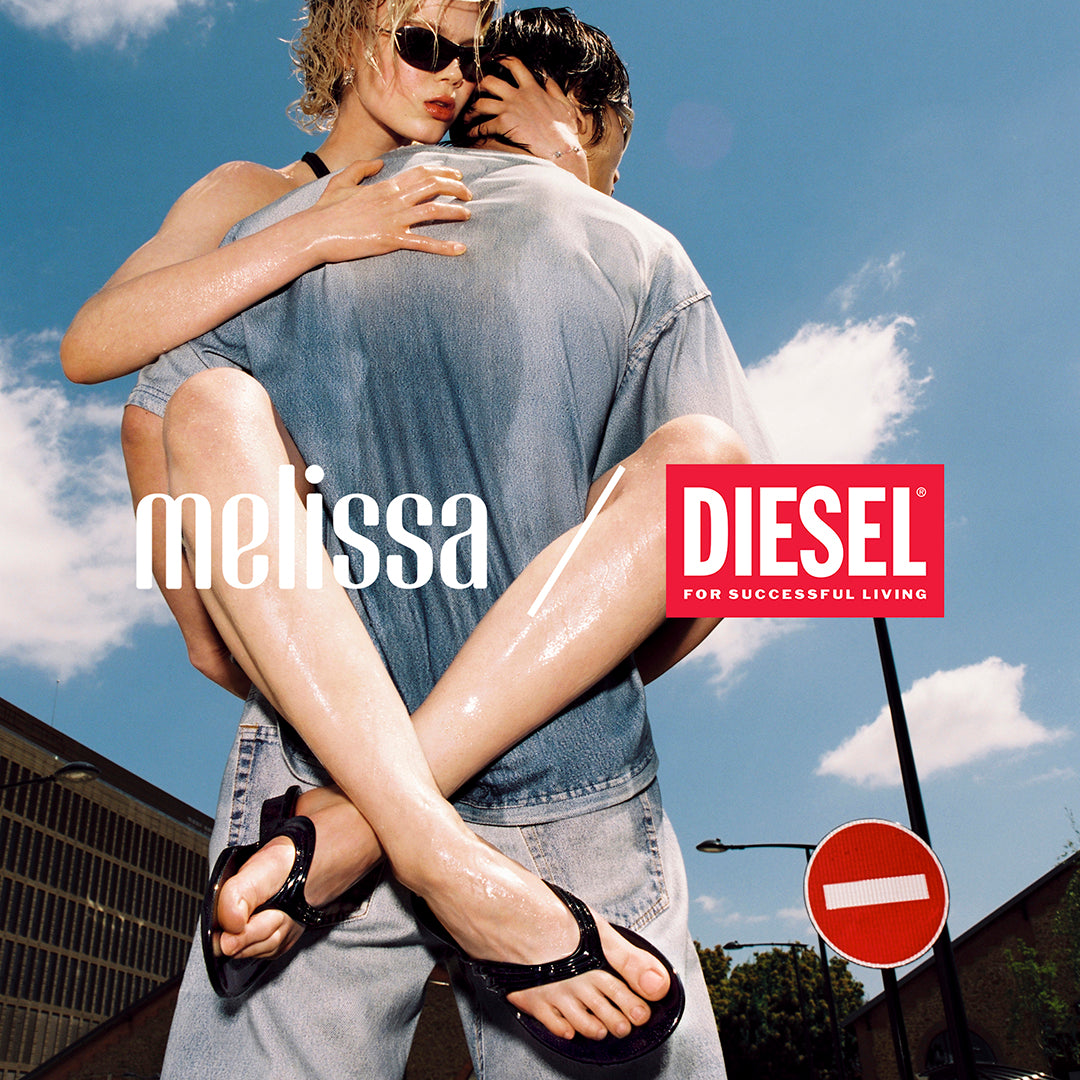

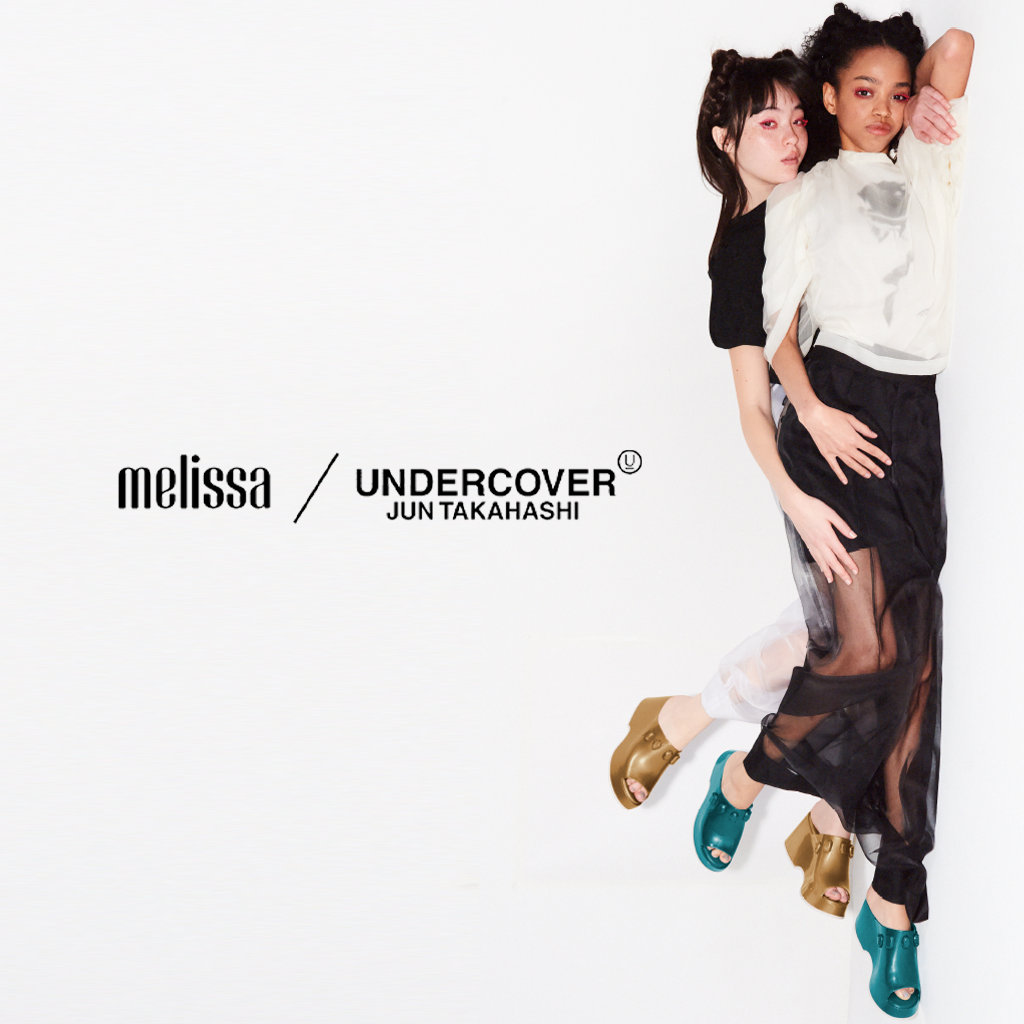

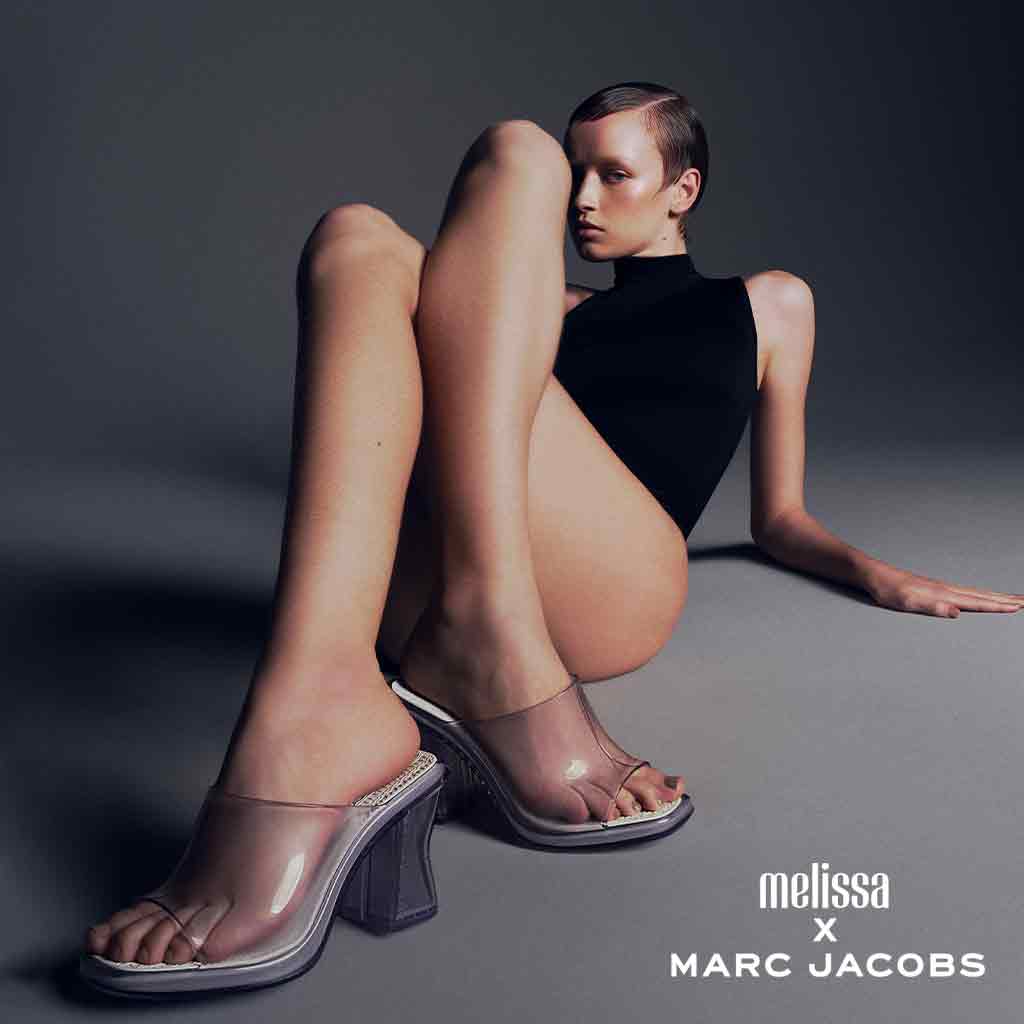

We conduct in-depth research and develop new materials and processes. And, as a bonus, we show that lower impact and beauty can go hand in hand. Swipe to see our styles!

MADE IN BRAZIL

It’s about valuing our country’s creative capacity, generating local opportunities, and strengthening a supply chain that puts people at the center.

This network, which includes employees as well as partners and suppliers, is a community that builds fashion through dignified work, driving local development and positive impact.

Across our facilities in Brazil’s South and Northeast regions, we bring together talent and skills to innovate ethically.

Grendene University has been in operation since 2017 and offers 104 courses. These include self-development, diversity, innovation and creativity, business, leadership and management, sustainability, productivity, tech and data, occupational health and safety, and code of ethics.

18,781 EMPLOYEES

237 SUPPLIERS

6,700 HOURS TRAINNING

ECO-EFFICIENCY

Eco-efficiency is about transforming the way we produce.

It means doing more with less impact, investing in innovation, and using resources wisely.

We have great examples of how this works at Melissa.

134 MILLION

litres of water reused in 2025

equivalent to about 54 Olympic-size swimming pools

100%

renewable electricity, I-REC certified

30%

of our shoes are made from pre-consumer recycled material

reducing the need for new raw materials

There’s no life without water. A no brainer, right? That’s why we adopt responsible practices in the use of this precious resource.We’ve implemented measures to ensure the conscious and efficient use of water in our processes. We continuously monitor our intake sources, seeking to optimize the use of our water resources, and, as a result, have achieved low levels of water consumption.And we spare no effort when it comes to investing in technologies and processes. Want to know some of them?

> Rainwater harvesting;

> Treatment and reuse of all effluent generated in industrial processes;

> Reuse of water used in production, avoiding waste;

> Constant monitoring of water consumption to continually find new ways to save.

Since 2021, the electricity consumption in our operations has been 100% from renewable sources. This is verified by the I-REC traceability seal.Grendene, the company we’re part of, has three of its own power plants with a total installed capacity of 3.27 MWp, located in Sobral and Crato (Ceará) and Farroupilha (Rio Grande do Sul). They supply part of the electricity demand for our operations. In 2024, we generated 4.25 GWh at Grendene, avoiding 1,899.97 tCO2e in emissions.

Melissa's production process is entirely in-house, which gives us complete control over our waste management.We don‘t send waste to landfills, prioritizing prevention, reduction, reuse, recycling, and energy recovery before final disposal.

TRANSPARENCY

We cultivate transparency, showcasing both our achievements and our challenges, including areas for improvement. Because transparency isn’t about being perfect, it's about celebrating and sharing what we learn along the way, in an honest dialogue that involves the entire fashion industry.

Since 2020, we've collaborated with the Fashion Transparency Index Brazil (FTIB). In the comparative edition released in 2024, we topped the list for advances in transparency in Brazil’s fashion industry.

We’re always improving our supplier policies and control mechanisms. Our commitment is to maintain a transparent, responsible network aligned with global sustainability best practices.

We use materials that undergo rigorous testing and follow strict controls on restricted substances. This means Melissa products are non-toxic and safe for both those who make them and those who wear them.

REVERSE LOGISTICS

WE HAVE THE POWER TO START OVER, ENDLESSLY

Since 2016, we’ve been building a circular path at Melissa: through the Reverse Logistics Program, our products leave the factory and can return to it at the end of their use cycle.

Here’s how it works:

1. We gather end-of-use shoes at collection points in cities across Brazil.

2. We send these shoes to our manufacturing facilities in northeastern Brazil.

3. We reintegrate the recovered material into the production cycle, supporting circularity.

WHAT ABOUT OTHER COUNTRIES?

We aim to expand our Reverse Logistics Program to all countries where we operate and continually seek viable local solutions and partners, focusing on scalability and sustainability.

CARBON FOOTPRINT

Stepping lighter on the planet

We work with concrete goals to reduce GHG emissions and are proud of the results we’ve achieved so far. Each pair of Melissa shoes generates only 254g CO2e*, a smaller footprint than conventional footwear**.To achieve this result, we carefully map our emissions across the entire production journey, from raw-material extraction to the final consumer.Through eco-efficient processes and the conscious choice of Melflex as our raw material, we’ve significantly reduced our emissions. The GHG Protocol seal reinforces our ongoing commitment to emissions management. It’s a journey that shows we can continue strengthening our brand without increasing our carbon footprint.

* Source: Grendene 2024 Sustainability Report

** Source: sustainability reports published in the footwear market

SUSTAINABILITY REPORT

For the sixth consecutive year, Melissa’s data has been published in the Grendene Sustainability Report, the company we’re part of. This document brings together our key social, environmental, financial, and governance information for 2024, offering a complete and transparent overview of Melissa’s commitments and results.

GRENDENE

Grendene is one of the largest footwear manufacturers in the world, and Melissa is one of its main brands. That’s over five decades of history! Throughout this journey, valuing people and caring for the environment have become fundamental pillars for us. All to create sustainable, accessible fashion through eco-efficient operations, responsible use of plastic, and the development of products with lower environmental impact.